On most jobs, the building never ends up exactly how the drawings showed it. Once the work starts, things shift a little here and there. A wall doesn’t land exactly on its planned line. A drain goes in at a slightly different depth because the ground wasn’t behaving the way everyone expected. A beam gets nudged to make space for other trades. None of this is unusual, it’s just how real sites work.

The trouble appears later when people still rely on the old drawings. Someone comes in to check levels or distances, and suddenly nothing matches. That’s when delays start, and Building Control asks questions nobody can answer. Small mistakes begin to cost time and money simply because no one updated the information.

An as-built survey clears this up. It records the site as it actually stands after the work is done. It’s not about the original plans anymore. It’s about what’s physically there now, the real positions, real levels, and real measurements. Building Control often asks for it, architects need it when preparing new designs, and developers include it in handover packs so the next team isn’t left guessing.

Having the correct information at the end saves people a lot of effort later on. It helps everyone understand the real layout of the project instead of working from outdated drawings.

1. What Exactly Is an As-Built Survey?

An as-built survey is simply a record of what ended up on the site once the work is finished. It’s not about what the drawings showed at the start. It’s about what is actually there now, the real positions, the real levels, and the real sizes of the built elements.

No project stays exactly the same from the first set of drawings to the last day on site. A beam moves a little, a drain sits at a slightly different depth, or a wall shifts because of access issues. Sometimes the client changes something halfway through. Sometimes the ground conditions force a small adjustment. These things happen on almost every job.

The as-built survey collects all of those changes in one place so the final drawing matches the real building, not the earlier plans. In simple terms, it tells you “this is how it ended up,” which is what most people need when they’re checking work, signing off stages, or planning anything new.

2. Why As-Built Surveys Are Important

A. Building Control Requirements

UK Building Control officers need accurate information before signing off a project.

They may ask for:

- Site levels

- Drainage routes and depths

- Boundary distances

- Finished floor levels

- Structural positions

If these details are wrong or missing, approval can be delayed.

B. Avoiding Disputes

Construction involves many parties, contractors, subcontractors, architects, and clients.

If a dispute arises, an as-built drawing acts as neutral evidence.

It shows exact measurements, which helps resolve disagreements without long arguments.

C. Tracking Deviations

Every project has small changes. Some are planned. Others happen naturally due to site conditions.

These deviations affect:

- Fire safety

- Joinery

- MEP routes

- Structural fit-out

- Future refurbishments

The as-built survey records these deviations so nothing is left unclear.

D. Planning Future Work

Architects and engineers need correct base information before starting a new extension or renovation.

If they design using outdated drawings, the new work may not fit the real building.

As-built surveys give them the confidence to plan accurately.

E. O&M Manuals and Handover

Many UK developers include as-built drawings inside their O&M (Operation and Maintenance) files.

This supports long-term building management and reduces guesswork for future teams.

3. When Do You Need an As-Built Survey?

A. At Practical Completion

This is the stage when the main building work ends.

The as-built survey here becomes the final record of the project.

Most developers, contractors, and homeowners request this version for:

- Building Control sign-off

- Handover files

- O&M manuals

- Warranty records

It shows the building exactly as it stands on the day work finishes.

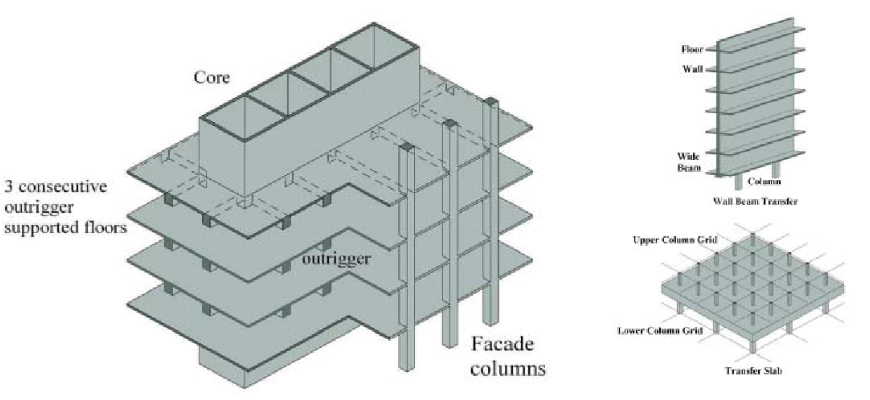

B. During Staged Construction

Large projects move in phases, and each phase may need its own check.

An as-built survey during these stages helps teams confirm that the previous work is correct before starting the next step.

Common stages include:

- Steel frame installation

- Concrete slab pours

- Blockwork and brickwork

- Roof installation

- Cladding and façade work

- MEP routes

If one stage is even slightly off, the next stage can face serious delays.

Staged as-built checks prevent this.

C. Foundations and Substructure

Foundations must be in the right place, at the right depth, and at the right level.

If they are not, the entire structure can shift or fail compliance checks.

An as-built survey at this stage confirms:

- Centreline positions

- Excavation levels

- Footing widths

- Pile caps

- Drainage runs under the slab

Many engineers request this before allowing work to continue above ground.

D. Extensions and Home Renovations

Homeowners often skip as-built checks, and this leads to planning issues later.

Architects may design an extension based on old drawings, only to find that the actual house does not match the plans.

An as-built survey is useful when:

- Extending a home

- Adding a loft room

- Changing internal layouts

- Adding outbuildings

- Joining two structures

It gives the architect accurate measurements so the new design fits the real building.

E. New Builds and Commercial Projects

For new builds, developers often collect as-built surveys for:

- Sales packs

- Lease plans

- Fire safety documentation

- Handover to management teams

Commercial properties, retail units, and office buildings all require accurate records for long-term management.

F. Regularisation Applications

G. Service Installation Checks

Drainage lines, cables, ducts, and utility routes rarely match the original drawings exactly.

A quick as-built survey confirms:

- Covers and manholes

- Pipe directions

- Invert levels

- Duct routes

- Cable trenches

This prevents clashes when new services are added in the future.

4. What Does an As-Built Survey Include?

A. Site Elements

These usually include:

- Ground levels across the site

- Boundary positions

- Drainage routes and depths

- Kerb lines

- Paths and hard surfaces

- Building footprint

For example, a drainage as-built may show the exact location of manholes, pipe directions, and invert levels.

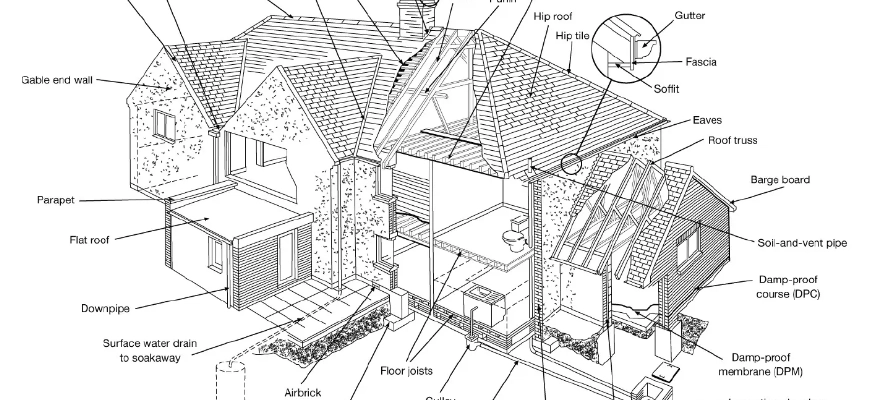

B. Building Elements

Inside a building, the survey can include:

- Wall positions

- Floor levels

- Ceiling heights

- Window and door openings

- Structural columns and beams

- Staircases

- Lift shafts

- Roof details

These details help design teams plan future changes without risk.

5. How As-Built Surveys Are Carried Out

A. Laser Scanning

Most modern as-built surveys use 3D laser scanners.

These devices capture millions of measurement points within minutes.

The result is a point cloud, which shows the building exactly as it stands.

B. Total Station and Control Points

Surveyors also set up control points to keep everything accurate.

A total station measures key spots, ensuring the survey aligns with site coordinates.

C. Processing and Drafting

After fieldwork, the point cloud and measurements move into CAD or Revit.

Surveyors then draw floor plans, elevations, site plans, or 3D models based on the captured data.

D. Verification and Quality Checks

Before issuing the final drawings, the team checks:

- Dimensions

- Levels

- Alignment

- CAD standards

- Missing features

This ensures the client receives a reliable record.

6. Typical Clients Who Use As-Built Surveys

As-built surveys support a wide range of clients, including:

- Main contractors

- Subcontractors

- Property developers

- Architects

- Structural engineers

- MEP engineers

- Local councils

- Housing associations

- Facility managers

Any project that needs accurate records at completion will benefit from an as-built survey.

7. Common Mistakes to Avoid

A. Relying on Contractor Drawings

Contractor drawings show what should have been built, not what was actually built.

If you use them as your final record, you may end up planning future work on outdated information.

Always get a fresh as-built survey so you know the measurements are correct.

B. Ignoring Drainage Levels

Drainage is one of the first things that changes on site. Pipe routes shift, levels drop, and manhole positions move slightly during installation.

If these updates are not recorded, Building Control may refuse sign-off, and later work can become difficult. A drainage as-built avoids these issues.

C. Surveying Too Late in the Build

Some areas become covered once finishes go in. Once floors, ceilings, or services are installed, reaching key points becomes harder.

A well-timed survey ensures the team captures vital details before they disappear behind finishes.

D. Missing Small Structural Changes

Small shifts in columns, beams, or walls can create larger problems later.

Even a small offset can affect door openings, service routes, or fire safety plans.

Recording these deviations early helps keep the project accurate and safe.

E. No Control Points on Site

Conclusion

Most problems on a site start when people make decisions without knowing what is actually there. An as-built survey fixes that. It gives everyone a clear picture of the finished work, with real measurements instead of old guesses. When the next team arrives, whether it’s Building Control, an architect planning an extension, or someone carrying out repairs, they can see the building as it truly is. That alone saves time, stops arguments, and keeps the project moving in the right direction.

At Survey2Plan, we handle these surveys for many different types of projects. Some are small home jobs, and some cover entire sites. If you want to check what information you need or you’re unsure about the process, you can speak to us and we’ll walk you through it. The aim is simple: give you drawings that match the real site so you don’t run into avoidable issues later.