Modern construction, renovation, and asset management projects demand high precision and time efficiency. Point cloud data has emerged as an essential foundation for accurate digital models in this landscape. When integrated with Revit, a powerful Building Information Modeling (BIM) tool, point cloud data allows professionals to replicate real-world conditions precisely.

This blog explores how point cloud data enhances Revit modeling, detailing its benefits, applications, workflow, and practical considerations.

What Is Point Cloud Data?

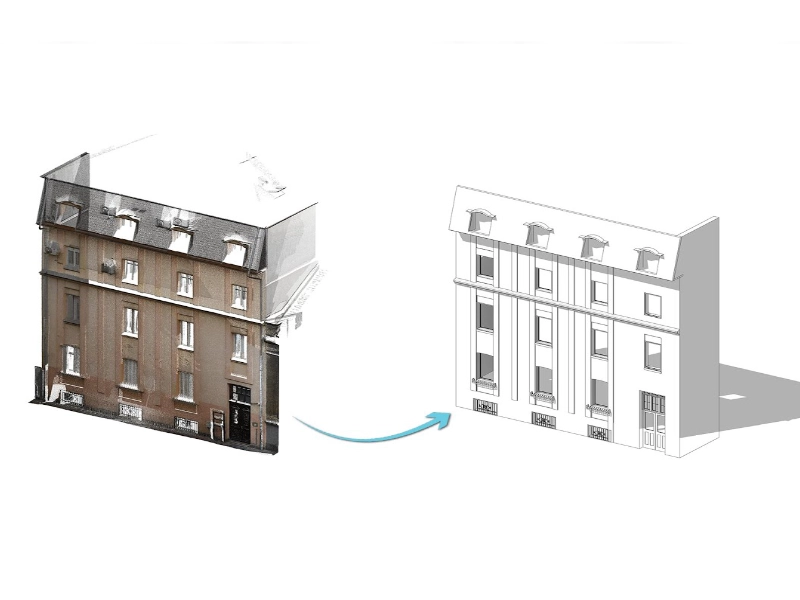

Point cloud data is a digital collection of countless spatial points captured from the surface of real-world environments. X, Y, and Z coordinates define each point in this 3D space. These points are usually captured using 3D laser scanners or LIDAR-equipped drones and cameras.

The resulting data accurately represents physical structures, whether a historical façade, a mechanical room, or an entire office block. This detailed data is essential when creating or verifying digital models, especially in environments lacking original plans.

Capturing Point Cloud Data

Point cloud data is collected using technologies like:

- Terrestrial Laser Scanning (TLS) for high-resolution, ground-based capture

- Mobile Mapping Systems (MMS) for walk-through scanning in large interior spaces

- Drone Photogrammetry for external structures and topographic areas

The scanner emits laser pulses and records their return time. The distance to each surface is calculated, forming a cloud of data points that collectively map the area with millimetre-level accuracy.

Once the scan is complete, the data is formatted into compatible file types such as. RCP, .e57, or. LAS, ready for Revit import.

What is Revit Modelling?

Revit is a leading BIM software that enables the creation of intelligent 3D models. Unlike simple CAD drawings, Revit models carry detailed metadata about each component’s materials, dimensions, system types, and phase construction information.

Revit is commonly used by:

- Architects designing buildings from scratch or refurbishing existing ones

- Engineers modelling structural, mechanical, and electrical systems

- Contractors planning construction phasing and coordination

- Facility managers maintain assets over the building lifecycle

When point cloud data is used as the base reference for Revit modeling, the output becomes both geometrically precise and information-rich.

Workflow: From Scan to Revit Model

- Site Visit and Scanning

High-definition laser scans are conducted, capturing every surface and fixture.

- Data Processing

The raw point cloud is cleaned and registered into a single cohesive dataset.

- Import into Revit

The processed data is brought into Revit, often as a linked reference.

- Modelling in Revit

Designers trace and recreate elements like walls, floors, and pipework over the scan.

- QA & Model Output

The final model is reviewed, checked against scan data, and exported in formats like. RVT or IFC.

Each step ensures that the digital model aligns exactly with the real-world building.

Key Benefits of Using Point Cloud Data in Revit Modeling

1. Precision from the Start

Point clouds provide unmatched spatial accuracy. When a laser scan captures a space, every angle, curve, and irregular surface is documented. Even minor deformations such as a slightly tilted beam, an uneven floor, or a misaligned window are picked up with millimetre accuracy.

When this data is imported into Revit, the resulting model reflects the actual built environment, not just assumptions based on paper drawings. This level of precision reduces the gap between design and reality, making it easier to plan, coordinate, and build with confidence.

2. Time Efficiency

Laser scanning is one of the fastest ways to gather building data. A full building spanning multiple floors can often be scanned in a matter of hours. Unlike traditional tape or total station surveys, scanners capture comprehensive data in a single visit.

This speed translates directly into faster Revit modelling. Instead of manually measuring spaces or cross-referencing inconsistent drawings, modelers can reference a complete digital twin. That saves hours, sometimes days, of pre-modelling time especially for large or complex properties.

3. Supports As-Built Documentation

For many projects, especially refurbishments, the final deliverable isn’t just a 3D model it’s an as-built record. This is particularly important for building compliance, regulatory sign-off, insurance documentation, and facility management.

Point cloud-based Revit models provide a reliable, verified snapshot of the building as it exists, not as it was intended. These models often form part of the digital handover, enabling owners and operators to manage their assets more efficiently over time.

4. Reduces Rework

Design rework is a common source of cost and delay in construction. Much of it stems from early inaccuracies often due to poor measurement or outdated drawings.

With point cloud data:

- Models are built on verified conditions

- Clash detection becomes more effective

- Site issues can be identified before breaking ground

This means fewer RFIs, fewer change orders, and fewer surprises during construction.

5. Enhances Team Collaboration

Modern construction involves multiple disciplines working in tandem—architectural, structural, MEP, fire safety, acoustic consultants, and more. A Revit model based on point cloud data becomes the central coordination platform for all parties.

Benefits include:

- Streamlined communication between disciplines

- Smoother BIM coordination meetings

- Enhanced planning through accurate quantity take-offs, phasing, and sequencing

When everyone works from the same base model, coordination improves, errors are caught early, and project momentum builds faster.

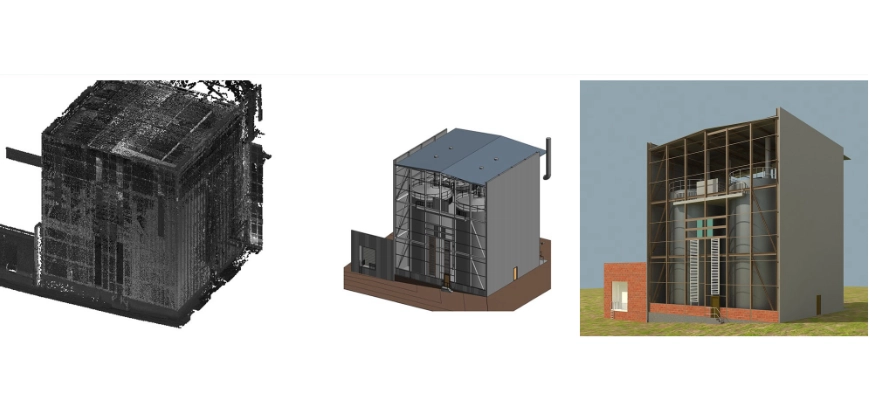

6. Ideal for Complex or Older Structures

Heritage buildings, industrial sites, or older commercial units often include irregular features that challenge traditional measurement methods. Curved walls, warped ceilings, and non-standard room geometries make it difficult to produce accurate floor plans using manual tools.

3D laser scanners have no such limitations. They capture everything exactly as it is including decorative elements, structural deformations, and tight or inaccessible areas. Revit modelers can then replicate these features with a high degree of realism, preserving the unique characteristics of the structure.

7. Cost-Effective Over Time

While laser scanning and Revit modelling may involve a higher upfront investment than basic 2D surveying, the long-term financial benefits are significant.

Cost savings include:

- Fewer site revisits

- Reduced project delays

- Avoided material over-ordering

- Faster design approvals

- Lower contractor variations

When stakeholders have access to dependable data from day one, decisions are faster, risks are lower, and budgets stay under control.

Use Cases for Point Cloud to Revit Modeling

Heritage Restoration

Restoring heritage properties demands precision without disturbance. Laser scanning is ideal because it’s entirely non-invasive it doesn’t touch the surfaces, nor does it require dismantling delicate structures. It captures all visible features in detail, including arches, cornices, timber beams, and stone carvings.

This data allows restoration teams to:

- Model intricate elements in Revit with a high degree of realism

- Compare current condition with past records

- Plan repair work without compromising the structure’s historical value

Point cloud modelling is often the first step in obtaining planning permission or grant funding for heritage conservation projects.

Commercial Fit-Outs

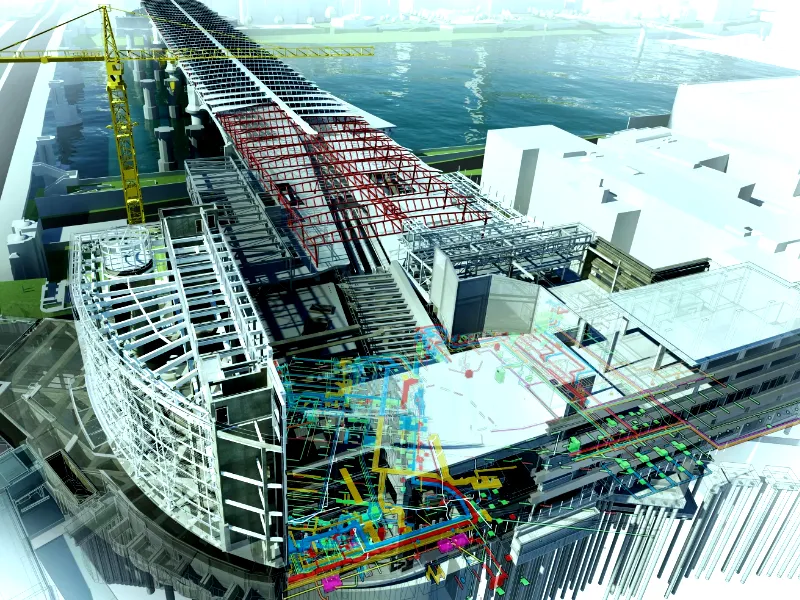

MEP System Coordination

Mechanical, electrical, and plumbing systems often occupy the tightest and most complex areas of a building. Installing or upgrading these systems especially in existing or occupied buildings requires precise planning. Without accurate spatial data, designers risk clashes between new services and existing structures, leading to time-consuming corrections on site.

By generating a point cloud and importing it into Revit, engineers gain access to highly accurate models of the ceiling voids, riser shafts, floor space, and service zones. This allows them to plan duct routes, electrical pathways, and fire suppression systems in full awareness of existing constraints.

Clash detection is far more effective when based on real-world geometry. Problems can be identified in the design phase rather than during installation, improving quality, reducing waste, and ensuring compliance with safety codes. This approach is especially useful in renovation projects where documentation is missing or outdated.

Industrial and Plant Environments

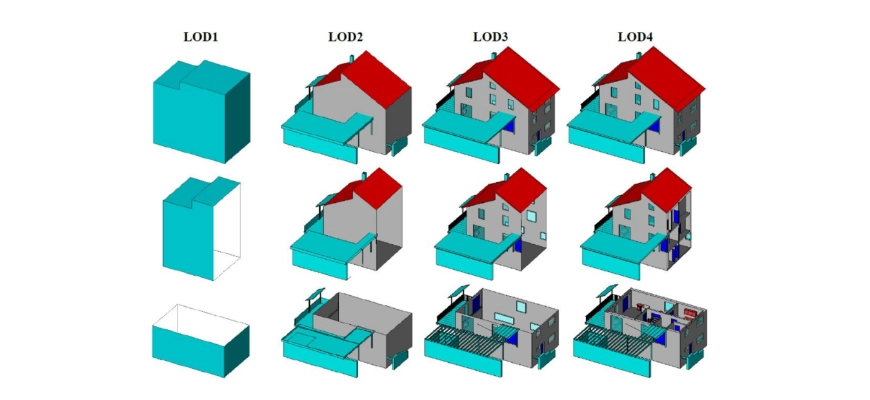

Level of Detail (LOD) in Revit Models from Point Cloud Data

The richness of your Revit model depends on the project requirements:

- LOD 100–200 for basic massing and design concepts

- LOD 300 for design intent and coordination

- LOD 400–500 for fabrication or asset management

Point cloud data can support all these levels, offering flexibility depending on the design, planning, or lifecycle management goal.

Data Quality Control and Accuracy Checks

Quality assurance is a critical part of scan-to-Revit workflows. This includes:

- Georeferencing and alignment to project coordinates

- Noise removal from stray reflections or moving objects

- Scan-to-model deviation analysis to check that modelled elements follow the scanned geometry

Survey2Plan ensures every step, from scanning to model delivery, meets quality benchmarks.

Challenges to Consider

Though powerful, this approach requires careful management:

- Large File Sizes

Point cloud files can be over 5–10 GB. Revit needs proper configuration to handle these smoothly.

- Software Requirements

Using plugins or companion software (like Autodesk Recap) may be necessary.

- Training Needs

Effective modelling from point cloud data requires experience. Poor scans or incorrect modelling can compromise the entire project.

Survey2Plan has addressed these challenges through trained specialists, advanced computing, and tested workflows.

Why Survey2Plan Stands Out

At Survey2Plan, we deliver high-quality point cloud to Revit modeling tailored to each project’s goals. Whether you’re planning a renovation, extension, or technical upgrade, we provide models that align precisely with your site.

What sets us apart?

- Expert surveyors and Revit specialists

- Fast turnaround times

- Detailed models at the right level of detail

- Support across multiple industries, including education, healthcare, and commercial development

Conclusion

Using point cloud data in Revit modelling isn’t just a technological upgrade. It’s a smarter way to work. It enhances precision, saves time, and supports every project lifecycle stage. From planning and design to construction and facilities management, this workflow reduces guesswork and improves confidence.

For teams seeking dependable, detailed digital models based on actual site conditions, point cloud to Revit modelling is the answer, and Survey2Plan delivers it with professionalism and precision.