In construction, even a small design error can lead to costly delays and material waste. According to industry studies, rework can account for up to 5% of total project costs and that doesn’t include the hidden impact of disrupted schedules, overtime labour, and damaged client trust.

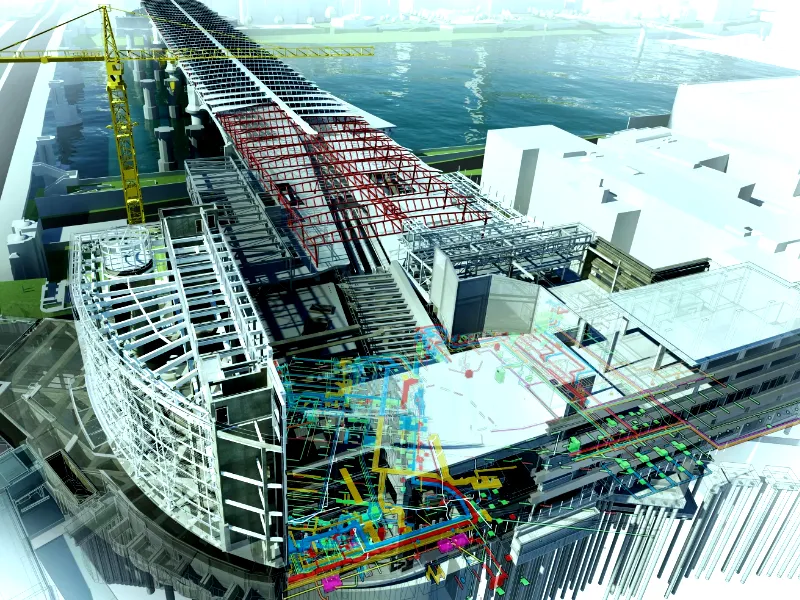

One of the biggest causes? Clashes when structural, architectural, and MEP (mechanical, electrical, plumbing) elements occupy the same space in the design but can’t coexist in reality.

Accurate BIM (Building Information Modelling) models are one of the most effective ways to detect and resolve these issues early long before they reach the site.

At Survey2Plan, our experience shows that the accuracy of the BIM model directly determines how much time, money, and frustration you can save. Let’s explore why.

Understanding Clashes in Construction

A clash occurs when different building systems physically interfere with one another. Examples include:

- A ventilation duct passing through a structural beam

- A plumbing pipe intersecting with an electrical conduit

- A lift shaft overlapping with fire escape routes

These conflicts are often missed when working from 2D drawings or outdated survey data, only to be discovered during construction resulting in demolition, redesign, and reinstallation.

The Role of Accurate BIM Models

A BIM model is only as good as the information it’s built on. If the input data is incomplete, outdated, or approximate, the resulting model may miss critical details allowing clashes to slip through unnoticed.

At Survey2Plan, we avoid this risk by starting with precision. Using 3D laser scanning and the Scan to BIM process, we capture every surface and feature of the existing site in millimetre-level detail. This ensures:

- True-to-site geometry – no guesswork or assumptions

- Exact placement of MEP systems – based on real measurements

- Reliable design coordination – across all disciplines

How Accurate BIM Models Reduce Rework

1. Early Clash Detection

2. Better Design Coordination

3. Fewer RFIs and Site Delays

4. Material and Labour Savings

Case Example: BIM Accuracy in Action

In a recent commercial fit-out project, the initial design was based on outdated 2D plans. Before work began, Survey2Plan carried out a 3D laser scan and created an accurate BIM model. Clash detection revealed that 35% of the original MEP layout conflicted with the structural frame.

By resolving these issues before site mobilisation:

- The project avoided 4 weeks of potential delays

- Over £25,000 in rework costs was saved

- Coordination meetings were reduced, freeing up valuable time

Why Accuracy Matters More Than Ever

As projects become more complex particularly in refurbishments, heritage buildings, and tight urban sites the margin for error is smaller. A model that’s only 95% accurate can still cause major problems.

With accurate BIM models:

- You spot issues early, when they are cheapest to fix

- You protect your schedule, avoiding costly overruns

- You deliver higher quality outcomes, improving client satisfaction

Survey2Plan’s Accuracy-First Approach

- High-precision 3D laser scanning of the entire site

- Detailed Revit modelling based on the point cloud

- Coordinated BIM deliverables ready for clash detection and project planning

Conclusion

Rework and clashes are not just inconvenient they are expensive and avoidable. By investing in accurate BIM models from the start, you give your project the best chance of finishing on time, on budget, and without unnecessary disruption.

At Survey2Plan, our precision-driven Scan to BIM services help project teams work with complete confidence reducing rework, eliminating clashes, and ensuring smoother project delivery from day one. Reduce Rework and Clash Errors with Accurate BIM Models